Table of Contents

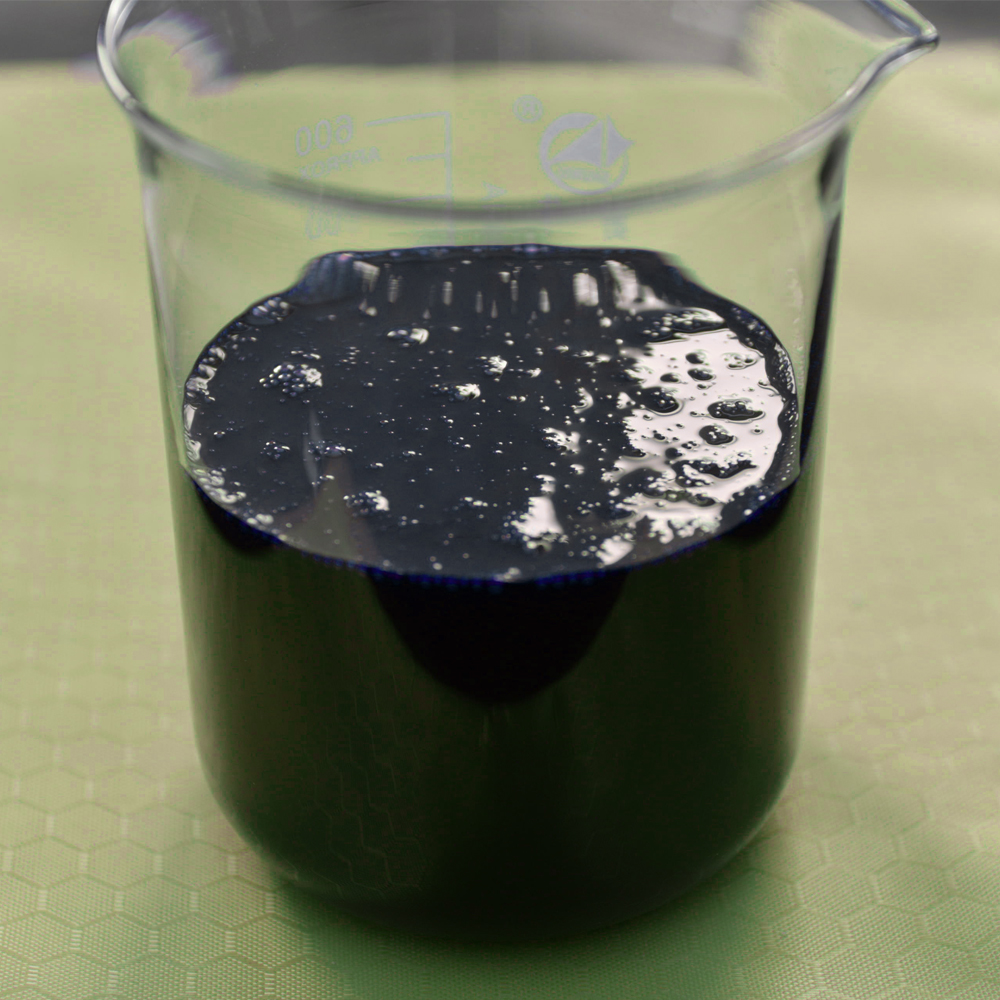

Bitumen Bonding Agent for Asphalt Adhesive

Asphalt adhesive is a crucial component in the construction and maintenance of roads, highways, and other infrastructure. It is used to bond layers of asphalt together, creating a strong and durable surface that can withstand heavy traffic and harsh weather conditions. However, one of the challenges faced by engineers and contractors is asphalt stripping, which occurs when the bond between the asphalt layers fails, leading to premature deterioration of the pavement.

| No. | Product |

| 1 | asphalt bonding agent Additive |

To address this issue, bitumen bonding agents are used as additives in asphalt adhesive to improve its resistance to stripping. These agents work by enhancing the adhesion between the asphalt binder and the aggregate, ensuring that the layers remain bonded together even under high stress and temperature fluctuations. By using a bitumen bonding agent, engineers can increase the longevity and performance of asphalt pavements, reducing the need for costly repairs and maintenance.

There are several types of bitumen bonding agents available on the market, each with its own unique properties and benefits. Some agents are designed to improve the adhesion of asphalt to aggregate surfaces, while others are formulated to enhance the cohesive strength of the asphalt binder itself. By selecting the right type of bonding agent for a specific application, engineers can tailor the performance of the asphalt adhesive to meet the requirements of the project.

In addition to improving the resistance to stripping, bitumen bonding agents can also enhance the overall durability and flexibility of asphalt pavements. These agents help to prevent cracking and rutting, which are common issues in asphalt surfaces exposed to heavy traffic and extreme weather conditions. By using a bonding agent with the right combination of properties, engineers can create pavements that are more resilient and long-lasting, reducing the need for frequent repairs and replacements.

When selecting a bitumen bonding agent for asphalt adhesive, engineers should consider factors such as the type of aggregate used, the climate and traffic conditions, and the desired performance characteristics of the pavement. It is important to work closely with manufacturers and suppliers to choose the right bonding agent for the specific requirements of the project, ensuring that the asphalt adhesive performs optimally and meets the desired performance standards.

In conclusion, bitumen bonding agents play a crucial role in improving the resistance to stripping of asphalt adhesive and enhancing the overall performance of asphalt pavements. By using the right type of bonding agent, engineers can create durable and long-lasting pavements that can withstand the rigors of heavy traffic and harsh weather conditions. With proper selection and application of bitumen bonding agents, engineers can ensure the longevity and performance of asphalt pavements, reducing the need for costly repairs and maintenance in the future.

Asphalt Stripping Resistance Additive for Asphalt Adhesive

Asphalt stripping resistance additive is a crucial component in asphalt adhesive formulations. This additive plays a key role in enhancing the bonding strength between asphalt and aggregate, ultimately improving the overall performance and durability of asphalt pavements. By preventing the stripping of asphalt from the aggregate surface, this additive helps to maintain the integrity of the pavement structure and prolong its service life.

One of the main functions of asphalt stripping resistance additive is to act as a bonding agent between the asphalt binder and the aggregate particles. This additive works by forming a strong chemical bond with both the asphalt binder and the aggregate surface, creating a cohesive bond that resists moisture penetration and prevents the stripping of asphalt from the aggregate. This enhanced bonding strength helps to improve the overall stability and durability of the asphalt pavement, reducing the risk of premature pavement failure.

In addition to improving bonding strength, asphalt stripping resistance additive also helps to enhance the adhesion properties of the asphalt adhesive. This additive works by increasing the surface energy of the aggregate particles, allowing for better wetting and adhesion of the asphalt binder. By improving the adhesion between the asphalt binder and the aggregate surface, this additive helps to create a more uniform and cohesive pavement structure, reducing the risk of cracking and rutting.

Furthermore, asphalt stripping resistance additive also plays a key role in enhancing the resistance of the asphalt pavement to moisture damage. By preventing the stripping of asphalt from the aggregate surface, this additive helps to reduce the permeability of the pavement structure, preventing water from infiltrating the pavement layers and causing damage. This improved moisture resistance helps to prolong the service life of the asphalt pavement and reduce the need for costly repairs and maintenance.

Overall, asphalt stripping resistance additive is a critical component in asphalt adhesive formulations, helping to improve bonding strength, adhesion properties, and moisture resistance of the pavement structure. By incorporating this additive into asphalt adhesive formulations, pavement engineers can enhance the performance and durability of asphalt pavements, ultimately extending their service life and reducing the overall lifecycle costs.

In conclusion, asphalt stripping resistance additive plays a crucial role in enhancing the performance and durability of asphalt pavements. By improving bonding strength, adhesion properties, and moisture resistance, this additive helps to create a more stable and long-lasting pavement structure. Pavement engineers should consider incorporating asphalt stripping resistance additive into their asphalt adhesive formulations to improve the overall quality and longevity of asphalt pavements.