Table of Contents

Benefits of Using Advanced Materials in Oil Casing Manufacturing

Oil casing plays a crucial role in the oil and gas industry, providing structural support and protection for the wellbore. Over the years, the development and application of advanced materials in oil casing manufacturing have made significant progress, leading to improved performance and durability. In this article, we will explore the benefits of using advanced materials in oil casing and how they have revolutionized the industry.

One of the key benefits of using advanced materials in oil casing is increased strength and durability. Traditional steel casing can be prone to corrosion and wear over time, leading to potential leaks and failures. By utilizing advanced materials such as high-strength alloys and composites, manufacturers can create casing that is more resistant to corrosion, abrasion, and other forms of degradation. This results in longer service life and reduced maintenance costs for oil and gas operators.

In addition to improved strength and durability, advanced materials also offer enhanced performance in extreme environments. Oil and gas wells are often subjected to high pressures, temperatures, and corrosive fluids, which can put significant stress on casing materials. Advanced materials are designed to withstand these harsh conditions, ensuring the integrity of the wellbore and preventing costly failures. This is especially important in offshore drilling operations, where the Environment can be particularly challenging.

Furthermore, the use of advanced materials in oil casing manufacturing can Lead to increased efficiency and cost savings. By using lighter-weight materials with superior mechanical properties, manufacturers can reduce the overall weight of the casing string, making it easier to handle and install. This can result in faster drilling times and lower operational costs for oil and gas companies. Additionally, the improved performance and durability of advanced materials can help extend the life of the well, reducing the need for frequent replacements and repairs.

Another benefit of using advanced materials in oil casing is improved environmental sustainability. Traditional casing materials can have a significant impact on the environment, both during manufacturing and disposal. Advanced materials are often more eco-friendly, with lower carbon footprints and reduced waste generation. This aligns with the growing trend towards sustainable practices in the oil and gas industry, as companies seek to minimize their environmental impact and comply with regulations.

Overall, the development and application of advanced materials in oil casing manufacturing have brought about numerous benefits for the industry. From increased strength and durability to enhanced performance in extreme environments, these materials have revolutionized the way oil and gas wells are constructed and maintained. By utilizing advanced materials, oil and gas operators can improve efficiency, reduce costs, and minimize their environmental footprint. As technology continues to advance, we can expect to see even more innovations in oil casing materials, further driving progress in the industry.

Innovations in Oil Casing Design for Enhanced Performance and Durability

Oil casing plays a crucial role in the oil and gas industry, providing structural support and protection for the wellbore. Over the years, the development and application of oil casing have made continuous progress, leading to innovations in design that enhance performance and durability. These advancements have been driven by the need to overcome challenges such as high pressure, corrosive environments, and extreme temperatures in oil and gas wells.

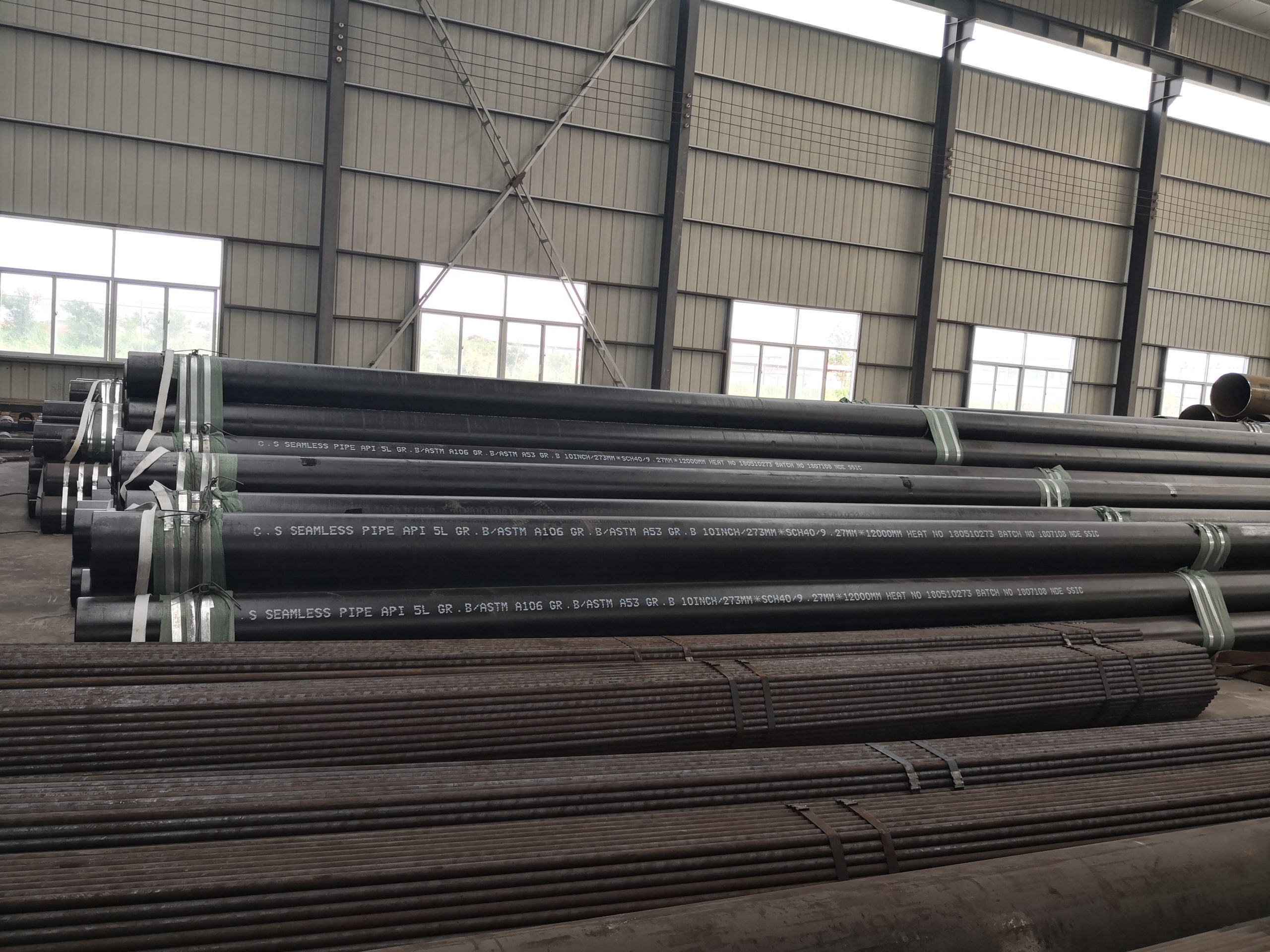

One of the key innovations in oil casing design is the use of high-strength materials such as Carbon Steel and Alloy Steel. These materials offer superior mechanical properties, including high tensile strength and impact resistance, which are essential for withstanding the harsh conditions encountered in oil and gas wells. By using high-strength materials, oil casing manufacturers can produce thinner and lighter casings without compromising on strength, allowing for easier installation and reduced costs.

In addition to high-strength materials, advancements in manufacturing processes have also contributed to the development of more durable oil casing. For example, the use of seamless casing technology eliminates the need for welding, which can weaken the casing and make it more susceptible to failure. Seamless casing is produced by extruding a solid billet of steel through a die to form a seamless tube, resulting in a casing with uniform wall thickness and improved structural integrity.

Furthermore, the development of corrosion-resistant coatings has helped to extend the service life of oil casing in corrosive environments. These coatings, such as epoxy, Zinc, and Polymer coatings, provide a protective barrier against corrosive agents such as hydrogen sulfide and carbon dioxide, which can cause premature failure of the casing. By applying corrosion-resistant coatings to the exterior of the casing, operators can ensure the integrity of the wellbore and prevent costly repairs and downtime.

Another important innovation in oil casing design is the use of premium connections, which are specially designed to provide a leak-proof seal and prevent gas migration in the wellbore. Premium connections feature a metal-to-metal seal that is more reliable than traditional threaded connections, reducing the risk of leaks and blowouts. Additionally, premium connections are designed to withstand high torque and axial loads, making them ideal for deepwater and high-pressure wells.

In recent years, the development of intelligent oil casing systems has revolutionized the way wells are monitored and controlled. These systems incorporate Sensors and communication technology to provide real-time data on well conditions, allowing operators to make informed decisions and optimize production. By monitoring parameters such as pressure, temperature, and flow rate, intelligent oil casing systems can detect anomalies and potential issues before they escalate, improving Safety and efficiency in oil and gas operations.

In conclusion, the development and application of oil casing have made significant progress in recent years, leading to innovations in design that enhance performance and durability. By using high-strength materials, seamless manufacturing processes, corrosion-resistant coatings, premium connections, and intelligent systems, oil casing manufacturers can produce casings that meet the demanding requirements of the oil and gas industry. These advancements have not only improved the reliability and longevity of oil casing but have also contributed to safer and more efficient oil and gas operations.