Table of Contents

The Process of Manufacturing C90/C95/T95/P110/Q125 Oil Casing Pipe in China

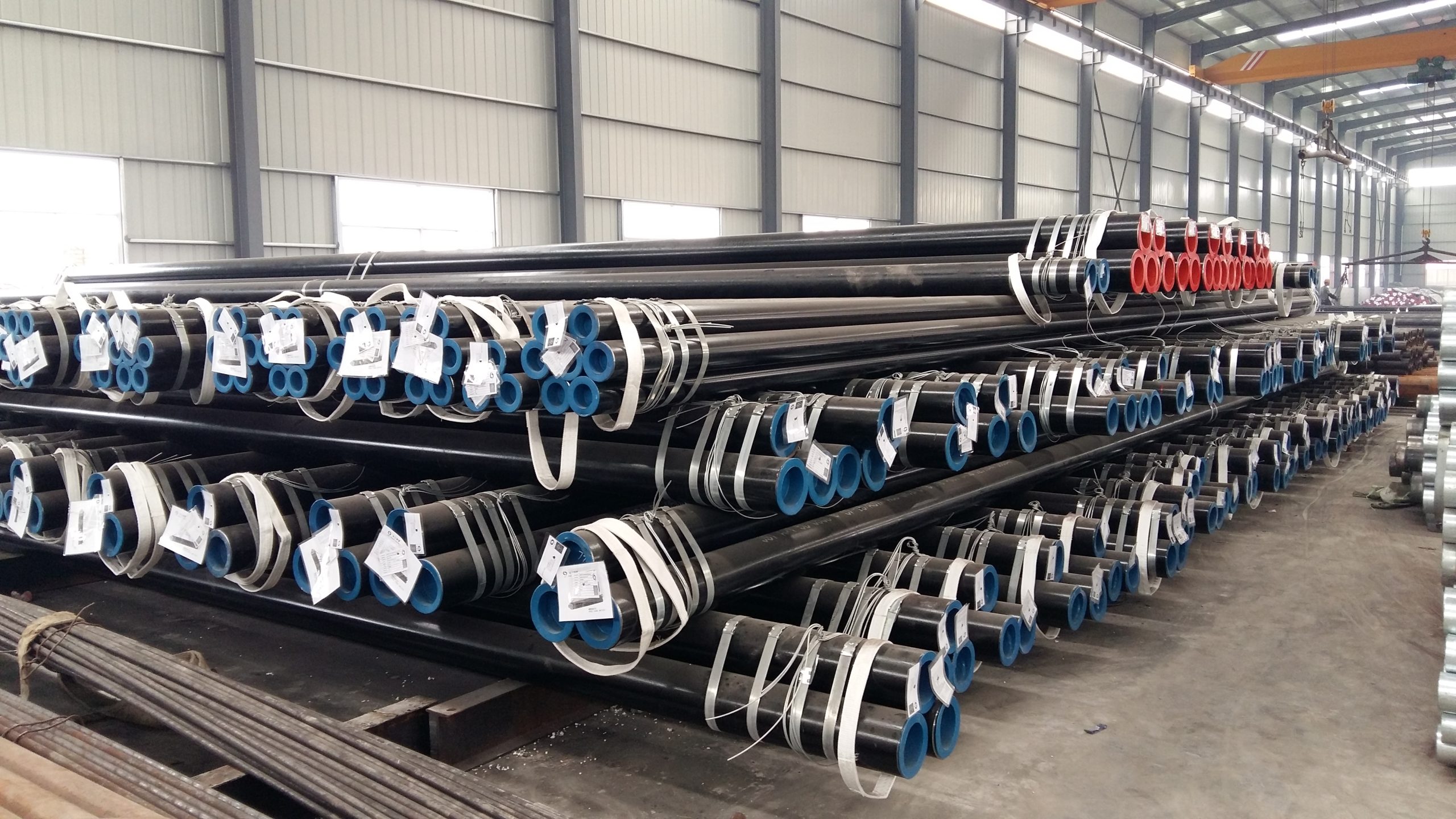

China has long been known as a global manufacturing powerhouse, producing a wide range of products for various industries. One such product that China excels in manufacturing is the C90/C95/T95/P110/Q125 oil casing pipe. These pipes are essential components in the oil and gas industry, used for drilling and extracting oil from deep underground reservoirs. In this article, we will explore the process of manufacturing C90/C95/T95/P110/Q125 oil casing pipes in China.

The manufacturing process of C90/C95/T95/P110/Q125 oil casing pipes begins with the selection of high-quality raw materials. In China, manufacturers typically use Carbon Steel or Alloy Steel to produce these pipes. These materials are chosen for their high strength, durability, and resistance to corrosion, making them ideal for use in harsh oil and gas drilling environments.

Once the raw materials are selected, they are melted in a furnace to form a molten metal. The molten metal is then poured into a mold to create the desired shape and size of the oil casing pipe. This process, known as casting, is crucial in ensuring that the pipe meets the required specifications and standards for use in the oil and gas industry.

After the casting process is complete, the pipe is subjected to various heat treatment processes to improve its mechanical properties. This includes processes such as quenching and tempering, which help to enhance the strength and toughness of the pipe. These heat treatment processes are essential in ensuring that the oil casing pipe can withstand the high pressures and temperatures encountered during oil and gas drilling operations.

Once the heat treatment processes are complete, the pipe is then subjected to a series of Machining operations to achieve the final dimensions and surface finish. This includes processes such as threading, which involves cutting threads on the ends of the pipe to allow for easy connection with other pipes and drilling equipment. The pipe is also inspected for any defects or imperfections that may affect its performance in the field.

Quality control is a critical aspect of the manufacturing process for C90/C95/T95/P110/Q125 oil casing pipes in China. Manufacturers adhere to strict quality standards and regulations to ensure that the pipes meet the required specifications and performance criteria. This includes conducting various tests and inspections, such as ultrasonic testing, magnetic particle inspection, and hydrostatic testing, to ensure the integrity and reliability of the pipes.

In conclusion, the process of manufacturing C90/C95/T95/P110/Q125 oil casing pipes in China is a complex and intricate process that involves various stages, from selecting high-quality raw materials to conducting heat treatment processes and machining operations. Through strict quality control measures and adherence to industry standards, Chinese manufacturers are able to produce high-quality oil casing pipes that meet the demanding requirements of the oil and gas industry. With China’s expertise and capabilities in manufacturing, it is no wonder that the country is a leading producer of C90/C95/T95/P110/Q125 oil casing pipes for the global market.