Table of Contents

What Is Considered Low Carbon Steel?

Low carbon steel is a type of steel that contains a low amount of carbon, typically less than 0.3%. This makes it one of the most common types of steel used in various industries due to its affordability and versatility. Low carbon steel is known for its strength and durability, making it suitable for a wide range of applications.

One of the key characteristics of low carbon steel is its malleability, which allows it to be easily formed into different shapes and sizes. This makes it ideal for manufacturing processes that require shaping and bending, such as in the production of automotive parts, construction materials, and machinery components. Additionally, low carbon steel is also known for its weldability, making it easy to join together using various welding techniques.

In terms of mechanical properties, low carbon steel is relatively soft and ductile compared to other types of steel. This makes it less prone to cracking or breaking under stress, making it a popular choice for applications that require a combination of strength and flexibility. However, low carbon steel may not be suitable for high-stress applications that require higher Levels of hardness and toughness.

Piano wire, on the other hand, is a type of high carbon steel wire that is known for its strength and resilience. It is typically made from a higher carbon content than low carbon steel, which gives it a higher tensile strength and hardness. Piano wire is commonly used in the manufacturing of piano strings, hence its name, due to its ability to withstand the tension and stress of being stretched across a piano frame.

In addition to its use in pianos, piano wire is also used in a variety of other applications that require a high level of strength and durability. For example, piano wire is often used in the production of Springs, surgical instruments, and Fishing Hooks due to its ability to maintain its shape and elasticity under pressure. The high carbon content of piano wire also makes it suitable for applications that require a sharp cutting edge, such as in the production of Razor Blades and cutting tools.

When it comes to alloy wheels, strength is a key consideration for many consumers. Alloy wheels are made from a combination of Aluminum and other metals, such as magnesium or Nickel, to create a lightweight yet strong wheel design. The use of alloys in wheel manufacturing allows for a higher strength-to-weight ratio compared to traditional steel wheels, making them a popular choice for performance vehicles and sports cars.

Alloy wheels are known for their durability and resistance to corrosion, making them a long-lasting and low-maintenance option for vehicle owners. The combination of aluminum and other metals in alloy wheels also provides improved heat dissipation, which can help prevent overheating and warping of the wheels under heavy braking or high-speed driving conditions.

In conclusion, low carbon steel, piano wire, and alloy wheels each have their own unique properties and applications. Low carbon steel is valued for its affordability and versatility, while piano wire is known for its strength and resilience. Alloy wheels offer a lightweight yet strong wheel design that is popular among performance vehicle enthusiasts. Understanding the characteristics of each material can help consumers make informed decisions when choosing the right material for their specific needs.

What Is Piano Wire Used For?

Low carbon steel is a type of steel that contains a relatively low amount of carbon, typically less than 0.25%. This makes it one of the most common types of steel used in various industries due to its affordability and versatility. Low carbon steel is known for its strength and durability, making it suitable for a wide range of applications.

One common use of low carbon steel is in the manufacturing of piano wire. Piano wire is a type of high-carbon steel wire that is known for its strength and flexibility. It is used in the construction of piano strings, as well as in other applications where a strong, flexible wire is needed. Piano wire is typically made from high-carbon steel, but low carbon steel can also be used in some cases.

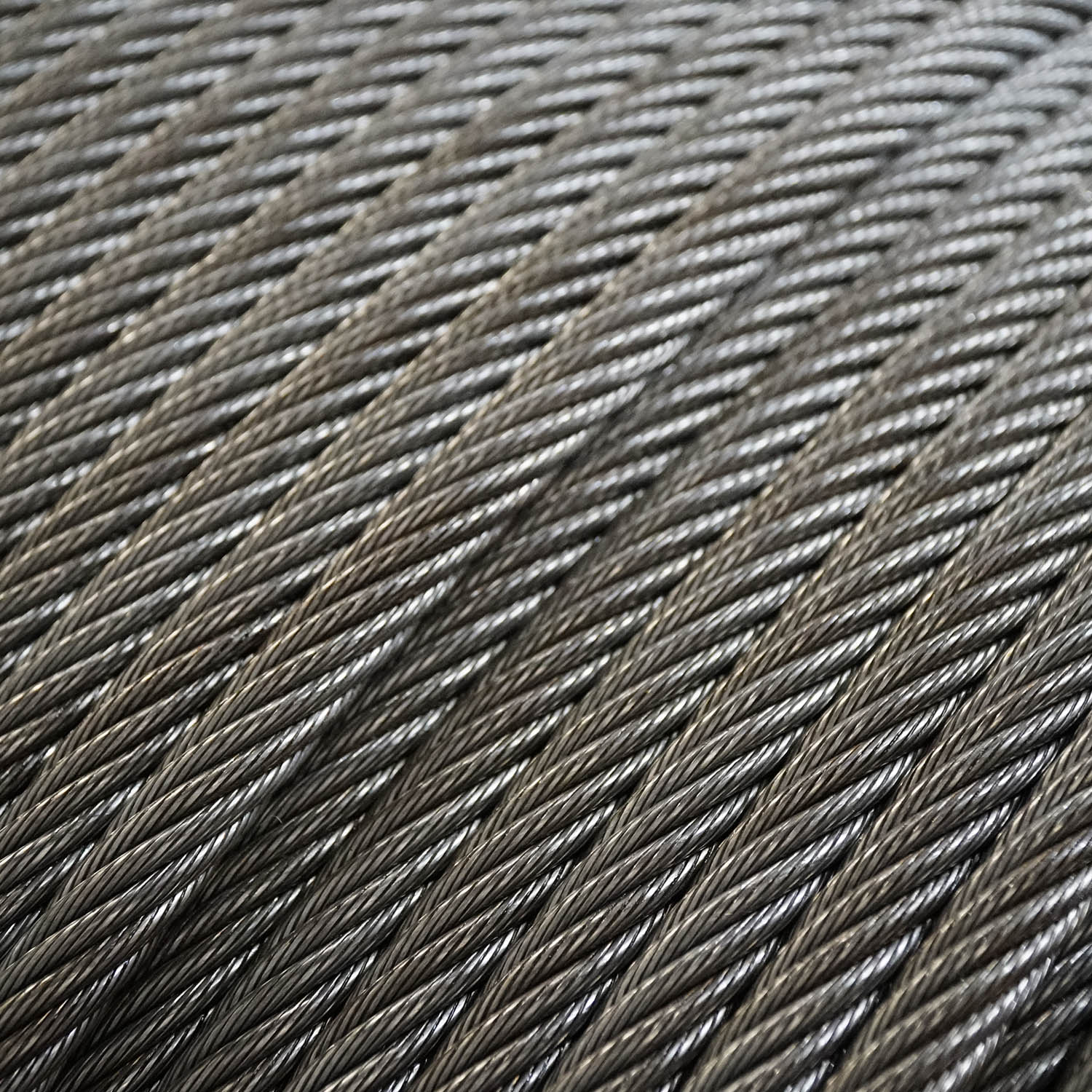

Piano wire is used in a variety of applications beyond just piano strings. It is commonly used in the manufacturing of springs, such as those found in automotive suspension systems and Industrial Machinery. Piano wire is also used in the construction of wire ropes, which are used in a variety of applications, including lifting and towing.

One of the key characteristics of piano wire is its high tensile strength, which allows it to withstand high levels of stress without breaking. This makes it ideal for applications where a strong, flexible wire is needed. In addition to its strength, piano wire is also known for its ability to maintain its shape and elasticity over time, making it a reliable choice for a wide range of applications.

In addition to its use in piano strings and other applications, piano wire is also used in the manufacturing of Musical Instruments, such as guitars and violins. The high tensile strength and flexibility of piano wire make it an ideal material for creating strings that produce clear, resonant tones. Piano wire is also used in the construction of wire brushes, which are commonly used in cleaning and polishing applications.

Another common application of low carbon steel is in the manufacturing of alloy wheels. Alloy wheels are wheels that are made from a combination of aluminum and other metals, such as magnesium or nickel. These wheels are known for their strength, durability, and lightweight construction, making them a popular choice for automotive enthusiasts.

Alloy wheels are designed to provide improved performance and handling compared to traditional steel wheels. The combination of aluminum and other metals in alloy wheels results in a wheel that is stronger and lighter than traditional steel wheels. This allows for better acceleration, braking, and overall handling of the vehicle.

In addition to their performance benefits, alloy wheels are also known for their aesthetic appeal. The unique design and finish of alloy wheels can enhance the appearance of a vehicle, giving it a more modern and stylish look. Alloy wheels are available in a wide range of styles and finishes, making it easy to find a set that complements the overall design of a vehicle.

Overall, low carbon steel is a versatile material that is used in a wide range of applications, from piano wire to alloy wheels. Its strength, durability, and affordability make it a popular choice for manufacturers in various industries. Whether it’s providing the strength and flexibility needed for piano strings or the performance and aesthetic benefits of alloy wheels, low carbon steel continues to be a valuable material in the manufacturing world.