Table of Contents

Optimizing Temperature Control Systems for Asphalt Mixing Plants

Asphalt mixing plants play a crucial role in the construction industry, producing the hot mix asphalt used for building roads, highways, and other infrastructure projects. One of the key factors in the production of high-quality asphalt is maintaining precise temperature control throughout the mixing process. Reliable temperature regulation is essential to ensure that the asphalt mixture is properly heated and mixed, resulting in a durable and long-lasting end product.

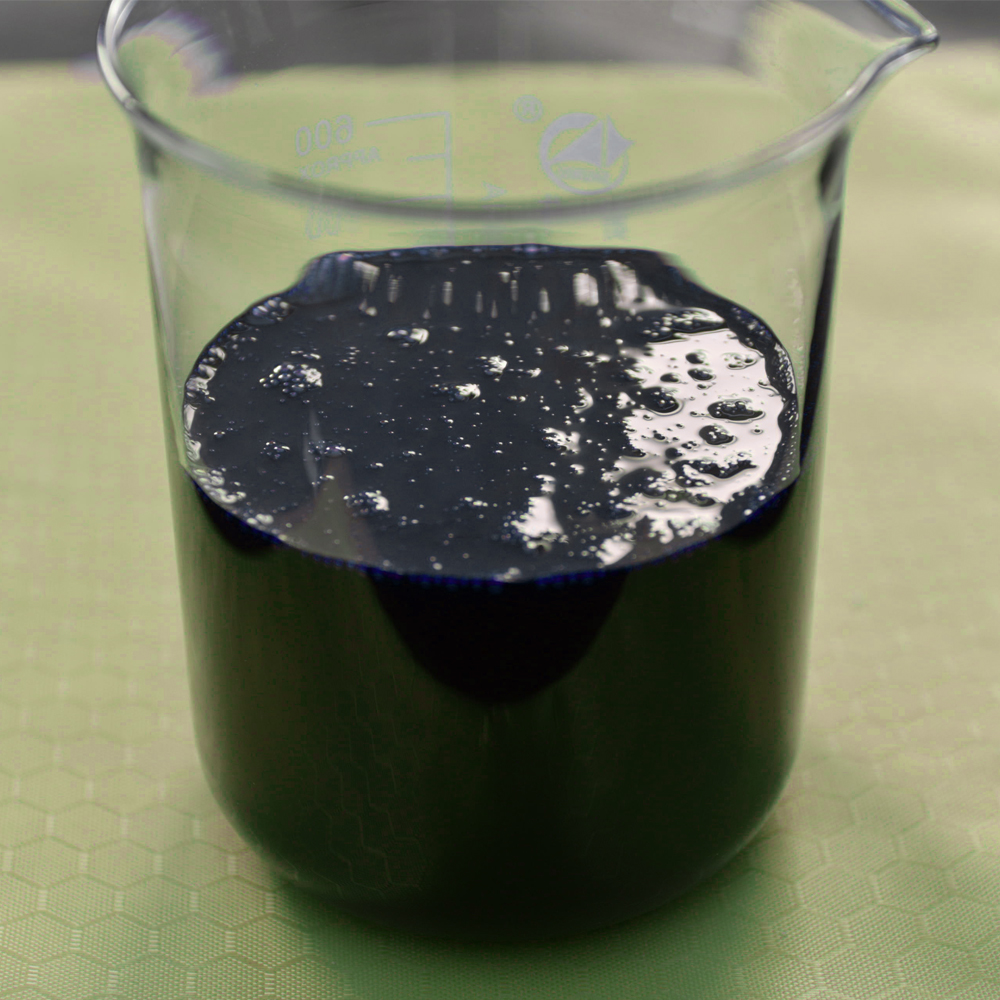

Temperature control systems in asphalt mixing plants are designed to monitor and adjust the temperature of the various components that make up the asphalt mixture, including aggregates, bitumen, and filler materials. These systems are responsible for ensuring that the materials are heated to the correct temperature before being mixed together, as well as maintaining the desired temperature throughout the entire mixing process.

| Nr. | Article Name |

| 1 | Warm Mix Asphalt Aid |

One of the main challenges in temperature regulation in asphalt mixing plants is the need to heat the materials to specific temperatures without overheating or underheating them. Overheating can cause the asphalt to become too viscous, leading to poor mixing and a lower-quality end product. On the other hand, underheating can result in incomplete mixing and a weaker asphalt mixture that is more prone to cracking and deterioration.

To address these challenges, asphalt mixing plants are equipped with advanced temperature control systems that use Sensors and controllers to monitor and adjust the temperature of the materials in real-time. These systems are programmed to maintain the temperature within a narrow range of tolerance, ensuring that the asphalt mixture is heated to the optimal temperature for mixing and compaction.

In addition to maintaining precise temperature control, asphalt mixing plants also utilize insulation and heating elements to prevent heat loss and maintain a consistent temperature throughout the mixing process. Insulation helps to retain heat within the mixing Drum and other components of the plant, while heating elements are used to supplement the heat generated by the combustion process.

Another important aspect of temperature regulation in asphalt mixing plants is the use of thermal imaging technology to monitor the temperature of the materials as they are being mixed. Thermal imaging cameras can provide real-time feedback on the temperature distribution within the mixing drum, allowing operators to make adjustments as needed to ensure uniform heating and mixing of the materials.

Overall, reliable temperature regulation is essential for optimizing the performance of asphalt mixing plants and producing high-quality asphalt mixtures. By investing in advanced temperature control systems, insulation, and thermal imaging technology, asphalt plant operators can ensure that their facilities are able to consistently produce durable and long-lasting asphalt for construction projects of all sizes. With proper temperature regulation, asphalt mixing plants can operate efficiently and effectively, delivering superior results that meet the highest standards of quality and performance.