Table of Contents

Benefits of Using Thermal Asphalt Blend Additives in Bituminous Warm Mixing Compound

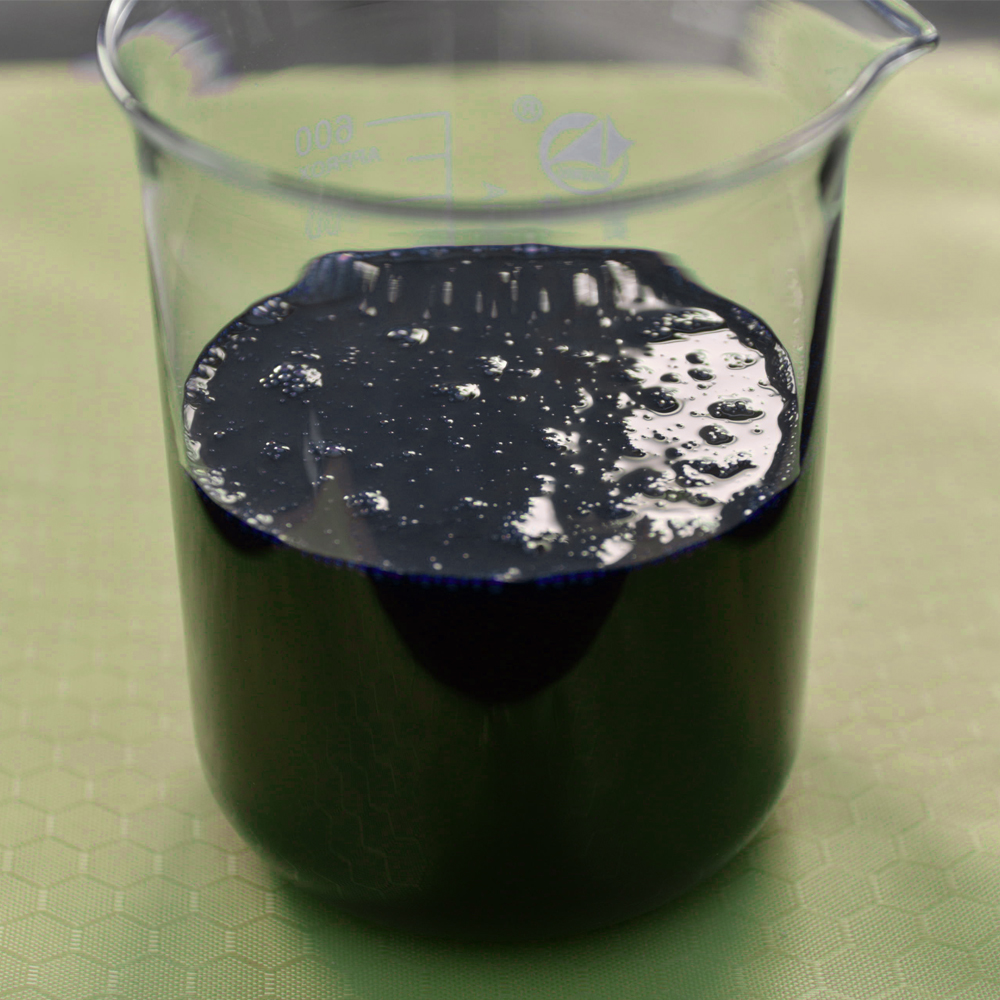

Thermal asphalt blend additives are becoming increasingly popular in the construction industry, particularly in the production of bituminous warm mixing compound. These additives offer a range of benefits that can improve the performance and longevity of road infrastructure. In this article, we will explore some of the key advantages of using thermal asphalt blend additives in bituminous warm mixing compound.

| Serial Number | Products |

| 1 | Warm Asphalt Mixing Agent |

One of the primary benefits of using thermal asphalt blend additives is the ability to reduce the production temperature of the bituminous warm mix. This can Lead to significant energy savings and reduced greenhouse gas emissions, making it a more environmentally friendly option compared to traditional hot mix asphalt. By lowering the production temperature, thermal asphalt blend additives also help to minimize the risk of worker exposure to harmful fumes and reduce the overall carbon footprint of road construction projects.

In addition to the environmental benefits, thermal asphalt blend additives can also improve the workability and compaction of bituminous warm mix. These additives help to lower the viscosity of the asphalt binder, making it easier to mix and apply. This can result in a more uniform and consistent mix, leading to better compaction and a smoother surface finish. Improved workability and compaction can also help to reduce the risk of rutting and cracking, extending the lifespan of the road infrastructure.

Furthermore, thermal asphalt blend additives can enhance the overall performance of bituminous warm mix by improving its resistance to moisture damage and aging. These additives help to create a more durable and resilient mix that can withstand the effects of heavy traffic, harsh weather conditions, and other environmental factors. By enhancing the moisture resistance of the mix, thermal asphalt blend additives can help to prevent stripping and raveling, which are common issues in traditional hot mix asphalt.

Another key benefit of using thermal asphalt blend additives is the potential for cost savings. By reducing the production temperature of bituminous warm mix, these additives can help to lower the overall energy consumption and production costs associated with road construction projects. Additionally, the improved workability and compaction of the mix can lead to faster construction times and reduced labor costs. Overall, the use of thermal asphalt blend additives can help to make road infrastructure projects more efficient and cost-effective.

In conclusion, thermal asphalt blend additives offer a range of benefits that can improve the performance and longevity of bituminous warm mix. From reducing production temperatures and energy consumption to enhancing workability and compaction, these additives can help to create a more sustainable and durable road infrastructure. By incorporating thermal asphalt blend additives into bituminous warm mixing compound, construction companies can achieve better results while also reducing their environmental impact and overall costs. As the demand for more sustainable and efficient road construction practices continues to grow, thermal asphalt blend additives are likely to play an increasingly important role in the industry.

How to Choose the Best Supplier for Bituminous Warm Mixing Compound Chinese

When it comes to road construction and maintenance, choosing the right supplier for bituminous warm mixing compound is crucial. This additive is used to improve the performance and durability of asphalt mixes, especially in cold weather conditions. With the growing demand for high-quality road infrastructure, it is essential to find a reliable supplier that can provide top-notch products.

One of the key factors to consider when selecting a supplier for bituminous warm mixing compound is the quality of their products. It is important to choose a supplier that offers high-quality additives that meet industry standards and specifications. This will ensure that the asphalt mixes produced with these additives are durable and long-lasting, even in harsh weather conditions.

In addition to quality, it is also important to consider the reputation of the supplier. A reputable supplier will have a track record of providing reliable products and excellent customer service. You can research online reviews and testimonials from other customers to get an idea of the supplier’s reputation in the industry.

Another important factor to consider when choosing a supplier for bituminous warm mixing compound is their pricing. While it is important to find a supplier that offers competitive prices, it is also crucial to consider the overall value of their products. A supplier that offers high-quality additives at a reasonable price is a better choice than one that offers low-quality products at a lower price.

Furthermore, it is essential to consider the supplier’s production capacity and delivery capabilities. A supplier with a large production capacity can ensure a steady supply of additives, even during peak construction seasons. Additionally, a supplier with efficient delivery capabilities can ensure that the products are delivered on time, minimizing delays in construction projects.

When selecting a supplier for bituminous warm mixing compound, it is also important to consider their customer service and technical support. A supplier that offers excellent customer service can provide assistance and guidance throughout the purchasing process. Additionally, a supplier that offers technical support can help you troubleshoot any issues that may arise during the use of their products.

In conclusion, choosing the best supplier for bituminous warm mixing compound Chinese is essential for the success of road infrastructure projects. By considering factors such as product quality, reputation, pricing, production capacity, delivery capabilities, customer service, and technical support, you can find a reliable supplier that meets your needs. Investing in high-quality additives from a reputable supplier will ensure that your asphalt mixes are durable and long-lasting, providing safe and reliable road infrastructure for years to come.